※横スクロールしてご覧ください。

全国新酒鑑評会(独立行政法人 酒類総合研究所主催)

平成 4 年 : 金賞受賞

平成 13 年 : 金賞受賞

平成 16 年 : 金賞受賞

平成 17 年 : 入賞

平成 19 年 : 金賞受賞

平成 20 年 : 金賞受賞

平成 21 年 : 金賞受賞

平成 22 年 : 金賞受賞

平成 23 年 : 入賞

平成 24 年 : 金賞受賞

平成 25 年 : 金賞受賞

平成 27 年 : 入賞

平成 28 年 : 入賞

平成 29 年 : 金賞受賞

令和 元 年 : 金賞受賞

令和 2 年 : 入賞

令和 3 年 : 金賞受賞

新潟県清酒鑑評会(新潟県杜氏組合連合会主催)

平成 11 年 : 新潟県知事賞受賞

名古屋国税局酒類鑑評会(名古屋国税局主催)

平成元年から11年連続入賞

平成 14 年 : 優等賞(吟醸酒部門)

平成 18 年 : 優等賞(市販酒部門) 「飛切り」「本醸造 天領」

平成 19 年 : 優等賞(市販酒部門) 「本醸造 天領」

平成 20 年 : 優等賞(市販酒部門) 「大吟醸 天領」「純米酒 天領」「本醸造 天領」

平成 21 年 : 優等賞(市販酒部門) 「大吟醸 天領」

平成 22 年 : 優等賞(市販酒部門) 「大吟醸 天領」「特選 天領」

平成 23 年 : 優等賞(市販酒部門) 「大吟醸 天領」「飛切り」

平成 24 年 : 優等賞(市販酒部門) 「大吟醸 天領」「本醸造 天領」

平成 25 年 : 優等賞(市販酒部門) 「大吟醸 天禄拝領」「本醸造 天領」

平成 26 年 : 優等賞(市販酒部門) 「大吟醸 天禄拝領」

平成 27 年 : 優等賞(市販酒部門) 「純米酒 天領」「本醸造 天領」

平成 28 年 : 優等賞(市販酒部門) 「大吟醸 天禄拝領」「純米酒 天領」

平成 29 年 : 優等賞(市販酒部門) 「大吟醸 天禄拝領」「本醸造 天領」

平成 30 年 : 優等賞(市販酒部門) 「大吟醸 天禄拝領」「純米酒 天領」

令和 元 年 : 優等賞(市販酒部門) 「大吟醸 天禄拝領」

令和 2 年 : 優等賞(市販酒部門) 「純米大吟醸 天禄拝領」「本醸造 天領」

岐阜県新酒鑑評会(岐阜県酒造組合連合会主催)

平成 6 年 第 1 回から6年連続入賞

平成 7 年 第 2 回 : 岐阜県議会議長賞受賞

平成 11 年 第 6 回 : 岐阜県議会議長賞受賞

平成 14 年 第 9 回 : 岐阜県知事賞受賞(本醸造酒の部)

平成 15 年 第 10 回 : 岐阜県知事賞受賞(本醸造酒の部)

平成 21 年 第 16 回 : 岐阜県議会議長賞受賞(本醸造酒の部)

平成 22 年 第 17 回 : 岐阜県議会議長賞受賞(本醸造酒の部)

平成 23 年 第 18 回 : 岐阜県議会議長賞受賞(純米醸造酒の部)

平成 25 年 第 20 回 : 岐阜県知事賞受賞(本醸造酒の部)

平成 26 年 第 21 回 : 岐阜県議会議長賞(吟醸酒の部)・岐阜県連合会長賞(純米酒、本醸造酒の部)

平成 27 年 第 22 回 : 岐阜県知事賞(本醸造酒の部)・岐阜県連合会長賞(本醸造酒の部)

平成 28 年 第 23 回 : 岐阜県議会議長賞(純米酒の部)・岐阜県連合会長賞(本醸造の部)

平成 29 年 第 24 回 : 岐阜県議会議長賞(純米酒の部)

平成 30 年 第 25 回 : 岐阜県議会議長賞(純米酒の部)

令和 2 年 第 27 回 : 岐阜県知事賞(本醸造酒の部)

令和 3 年 第 28 回 : 岐阜県議会議長賞(大吟醸の部)

日本チャンピオンズカップ(3年連続入賞)

2005 年 : ベストカップ賞(ゴールドメダル) 「天領(銀)カップ」

2006 年 : ベストカップ賞(ゴールドメダル) 「さるぼぼカップ」

2007 年 : ベストカップ賞(ゴールドメダル) 「さるぼぼカップ」

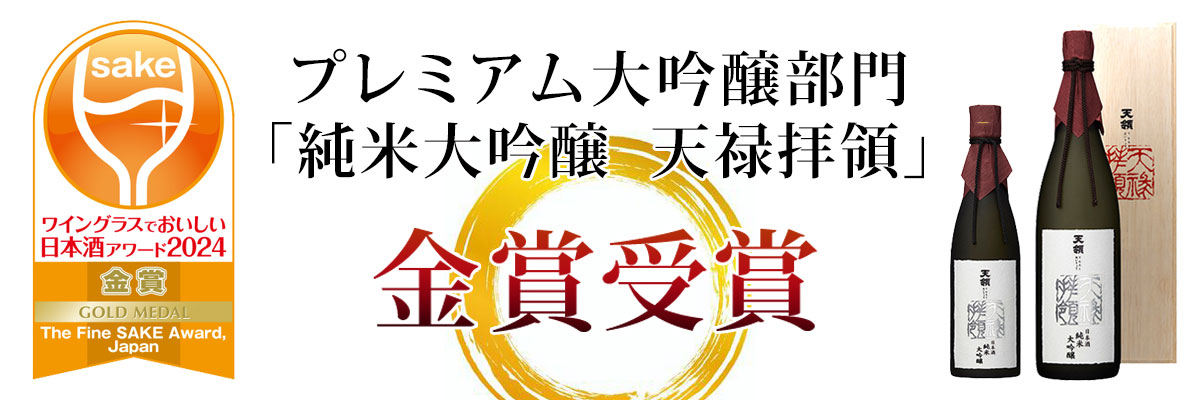

ワイングラスでおいしい日本酒アワード

2011年 金賞受賞「大吟醸 天禄拝領」

2012年 金賞受賞「純米吟醸 ひだほまれ 天領」「大吟醸 天禄拝領」

2015年 最高金賞受賞「大吟醸 天禄拝領」

2015年 金賞受賞「大吟醸 ひだほまれ天領」「大吟醸 吟」「純米大吟醸 天禄拝領」

2018年 金賞受賞「純米吟醸 ひだほまれ天領」

スローフードジャパン 燗酒コンテスト

2011年 金賞受賞 「特別純米酒 飛切り」「純米酒 天領」

2012年 熱燗部門金賞受賞 「上撰 天領」

海外でのコンテスト

2007 : U.S.A National Sake Appraisal (SILVER) 「大吟醸天のしずく」

2007 : International SAKE challenge (BRONZE) 「純米吟醸ひだほまれ」

2007 : San Francisco WINE COMP. (SILVER) 「純米吟醸ひだほまれ」

2007 : San Francisco WINE COMP. (BRONZE) 「純米大吟醸天領古酒」

2007 : World Wine Championships (SILVER) 「純米大吟醸天領古酒」

2007 : World Wine Championships (BRONZE) 「純米吟醸ひだほまれ」

2008 : モスクワ・インターナショナル・ワイン・アンド・スピリッツ・コンペティション

金賞「天禄拝領」クリスタルグラス賞「純米吟醸ひだほまれ天領」

2011 : San Francisco WINE COMP. (DOUBLE GOLD)

--最高賞--「純米大吟醸天領古酒」

2012 : WINE &SPIRITS WHOLE SALERS OF AMERICA (DOUBLE GOLD & BEST-SHOW )

--2賞同時受賞--「純米吟醸 ひだほまれ天領」

2018 : KURA MASTER2018 純米大吟醸酒&純米吟醸部門 プラチナ賞受賞 「純米大吟醸 天禄拝領」

2018 : KURA MASTER2018 純米大吟醸酒&純米吟醸部門 金賞受賞 「大吟醸 天禄拝領」

2018 : IWC2018(インターナショナル・ワイン・チャレンジ)銀メダル受賞 「純米大吟醸 天禄拝領」

2018 : IWC2018(インターナショナル・ワイン・チャレンジ)スパークリング酒の部

銅メダル 「スパークリング日本酒すますま」

2018 : IWC2018(インターナショナル・ワイン・チャレンジ)大吟醸の部 大会推奨酒 「大吟醸 吟」

2018 : SAKE selection2018 スパークリング日本酒部門 シルバー賞 「スパークリング日本酒すますま」

写真は、2012年第69回WINE &SPIRITS WHOLE SALERS OF AMERICA授賞式後。

右写真は、ニューヨーク市の寿司レストラン「SOTO」(日本食レストランとして全米で初のミシュラン星付を獲得 現在2つ星)のご主人、小杉外博氏(右)と弊社NY在社員、上野田又輔(左)です。

採用・出展

日本航空(JAL)

2005~2009 : 国際線エグゼクティブクラスで「純米大吟醸 天領」が使用されました。

2011.9 : 国内線ファーストクラスで「大吟醸 天領」が使用されました。

2012.1 : 国内線ファーストクラスで「大吟醸 天領」が使用されました。

国際航空ショー

2010.6 : 「大吟醸 天領」が、パリ国際航空ショー「日本ブース」で各国のVIPへの土産品として使用されました。

2011.6 : 「大吟醸 天領」が、ファンブロー(英国)国際航空ショー「日本ブース」で各国のVIPへの土産品として使用されました。

海外での事業

2012.06 : 岐阜県トップセールス事業で、知事とシンガポール同行

2012.10 : 香港「ワイン アンド ダイン フェスティバル」共同出展

2012.11 : 香港シャングリラホテルにて「天領ディナー」開催

2013.04 : オーランド(米国)ワイン&スピリッツ ショー出展

2013.05 : 台北 日本の観光・物産展に出展